Křížové zapuštěné houbové šrouby

Odeslat dotaz

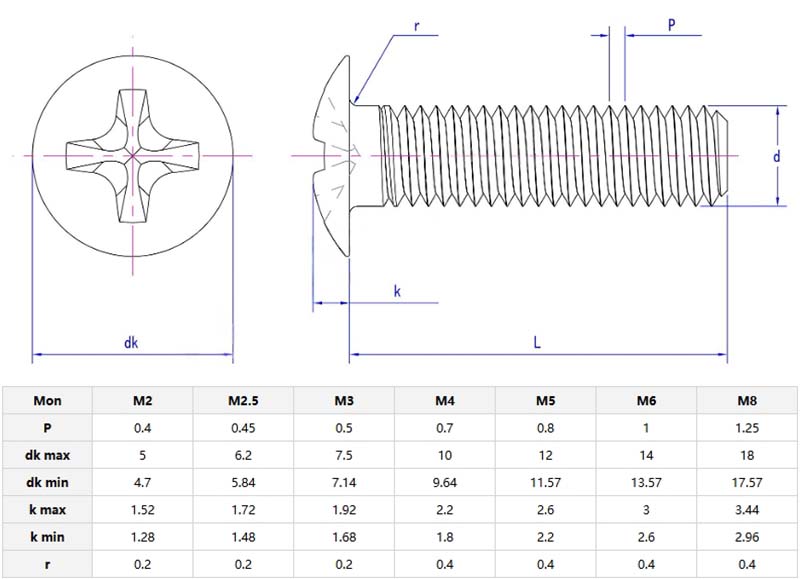

Cross recessed mushroom screws meet strict international quality standards, such as ISO 7045 (for raised countersunk head screws) and DIN 965 (for precise dimensions). The materials used are RoHS compliant and free of hazardous substances, allowing them to be used in electronic and medical devices.Aerospace versions go through tough testing to ensure they resist fatigue and distribute weight well. Certifications like REACH and ASTM F593 (for stainless steel fasteners) prove the materials are genuine and safe.

Xiaoguo® manufacturer follow relevant quality standards and provide screws that meet customer requirements. Cross recessed mushroom screws are used in regulated industries, from automotive manufacturing to construction projects that require certified hardware.There’s also documentation available, including material test reports, to help with quality checks during audits.

Advantages

Cross recessed mushroom screws aren’t expensive, especially since they’re mass-produced. If you buy a lot at once, each screw costs less – great for big jobs. They hold up well over time, so you won’t need to swap them out often. The cross-head design stops your screwdriver from slipping when you’re putting them in, which means faster work and less tool damage. They work with pretty much any material or finish you’re using, so you don’t have to stock ten different screw types. This makes it easier to keep track of your supplies. Whether you’re running a small shop or a full factory, they’re a solid basic choice,does the job without costing a fortune.

FAQ

Q: What corrosion-resistant treatments are available for cross recessed mushroom screws, and which is best for marine environments?

A: Cross recessed mushroom screws are rust resistant using zinc plating, electroplating or passivation. In marine areas or locations with high humidity, screws made of 316 stainless steel (grade A4) with a marine grade coating can effectively prevent rust and reduce replacement costs. These screws have been tested to salt spray standards (such as ASTM B117) and have a corrosion resistance of more than 500 hours. The mushroom head is sealed to effectively prevent the ingress of moisture. Hot-dip galvanized (HDG) cross recessed mushroom head screws are more rust and corrosion resistant, making them ideal for use in marine or coastal areas, while still being used with cross or Pozidrive screwdrivers.