Šrouby hlavy hexagonu

Odeslat dotaz

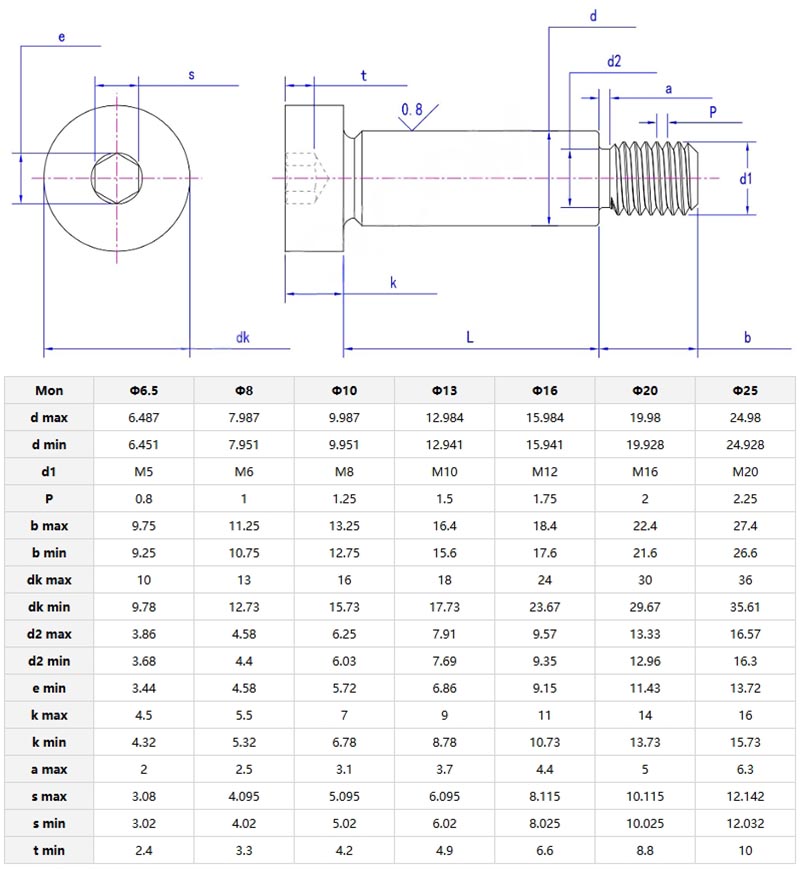

The hexagon socket head shoulder screws are made of solid material, with a cylindrical head and hexagonal grooves. It is widely used in machinery, automobiles and other scenes. When using it, you need to control the force. Over-tightening will dirty the hexagonal hole or damage the thread, so don't tighten it too hard when twisting it for installation. The way to make the hexagon socket head shoulder screw last for a long time is to brush off the dirt on the thread with a soft brush and alkaline solvent to keep the thread clean. Apply some anti-seize lubricant to the rust-prone position before installation to delay the rust of the screw.

Give the hexagon socket head shoulder screws a quick check every so often for wear, rust, or wobbles, especially in shaky machines. If any screws look busted, swap them out ASAP to avoid bigger issues. Store the screws in a dry and sealed container when not in use to reduce the chance of rust. The screws need to be regularly observed and maintained, and replaced in time if there is a problem, so as not to affect the working condition of the equipment.

How to choose?

Choosing hexagon socket head shoulder screws mostly depends on where and how you’re using them. If it’s wet, salty, or needs to stay clean (like boats or medical gear), go with stainless steel (304/316). For heavy-duty machines, grade 12.9 alloy steel can take serious weight. Aluminum’s lighter weight works for cars, planes, or stuff where pounds matter. Need no magnetic pull? Brass or titanium. Just double-check with the supplier to confirm the material’s rust resistance, heat tolerance, or conductivity actually do what you need.

Benefits in High-Vibration Environments

Q: How do hexagon socket head shoulder screws compare to other fastener types in high-vibration environments?

A: Hexagon socket head shoulder screws work really well in places with a lot of vibration. Their inner hexagonal shape lets tools grip tighter, which means the wrench is less likely to slip out compared to Phillips or slotted screws. The flat head doesn’t stick out much, so there’s less chance of it catching on something or coming loose when things are shaking. If you use them with thread-locking glue or serrated flange bolts, they’re even better at staying tight in vibrating conditions. They’re made with precise machining, so you can apply torque consistently.